99.7+%, 99.4+%, & 98.0+%

MgO

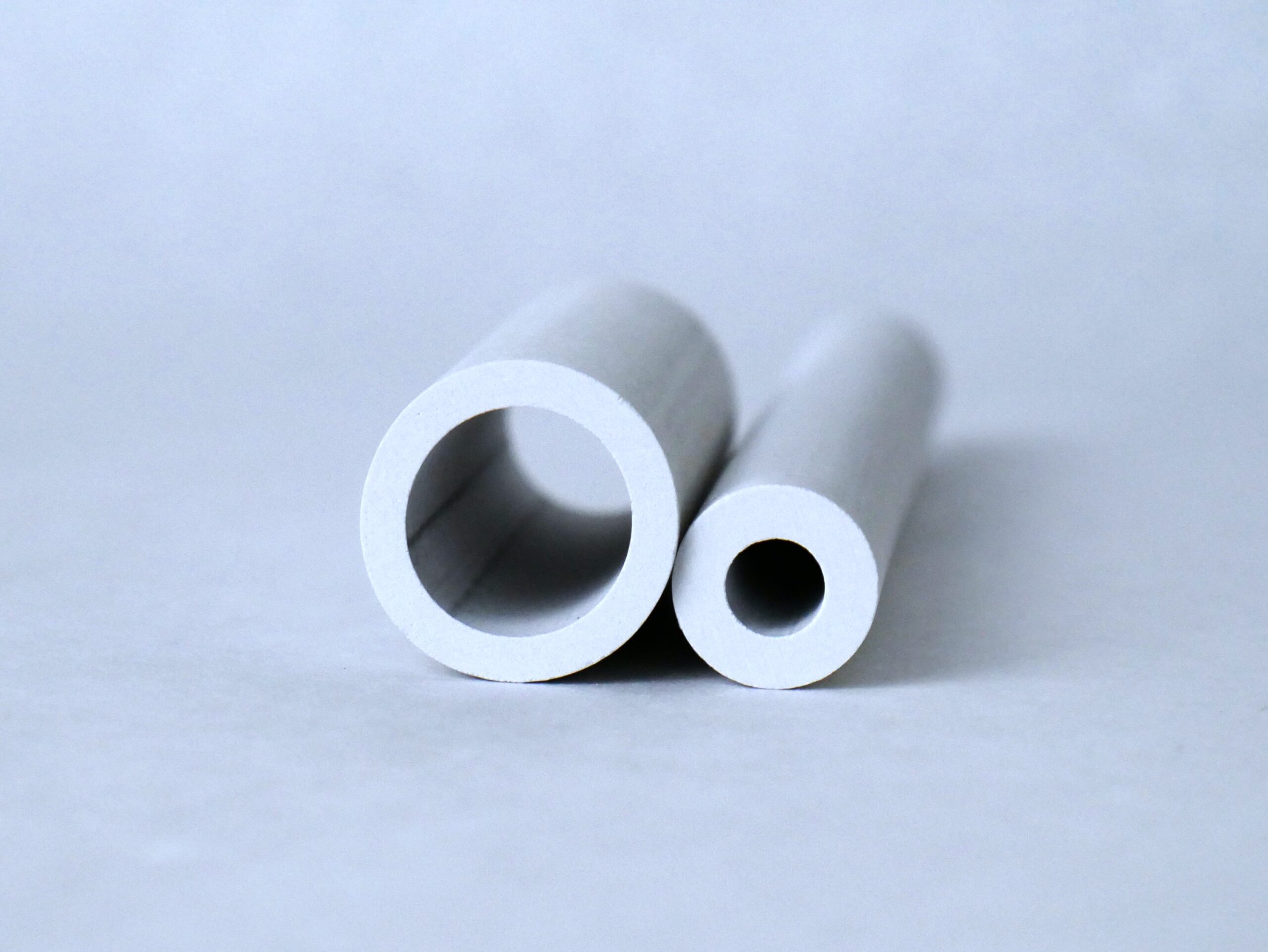

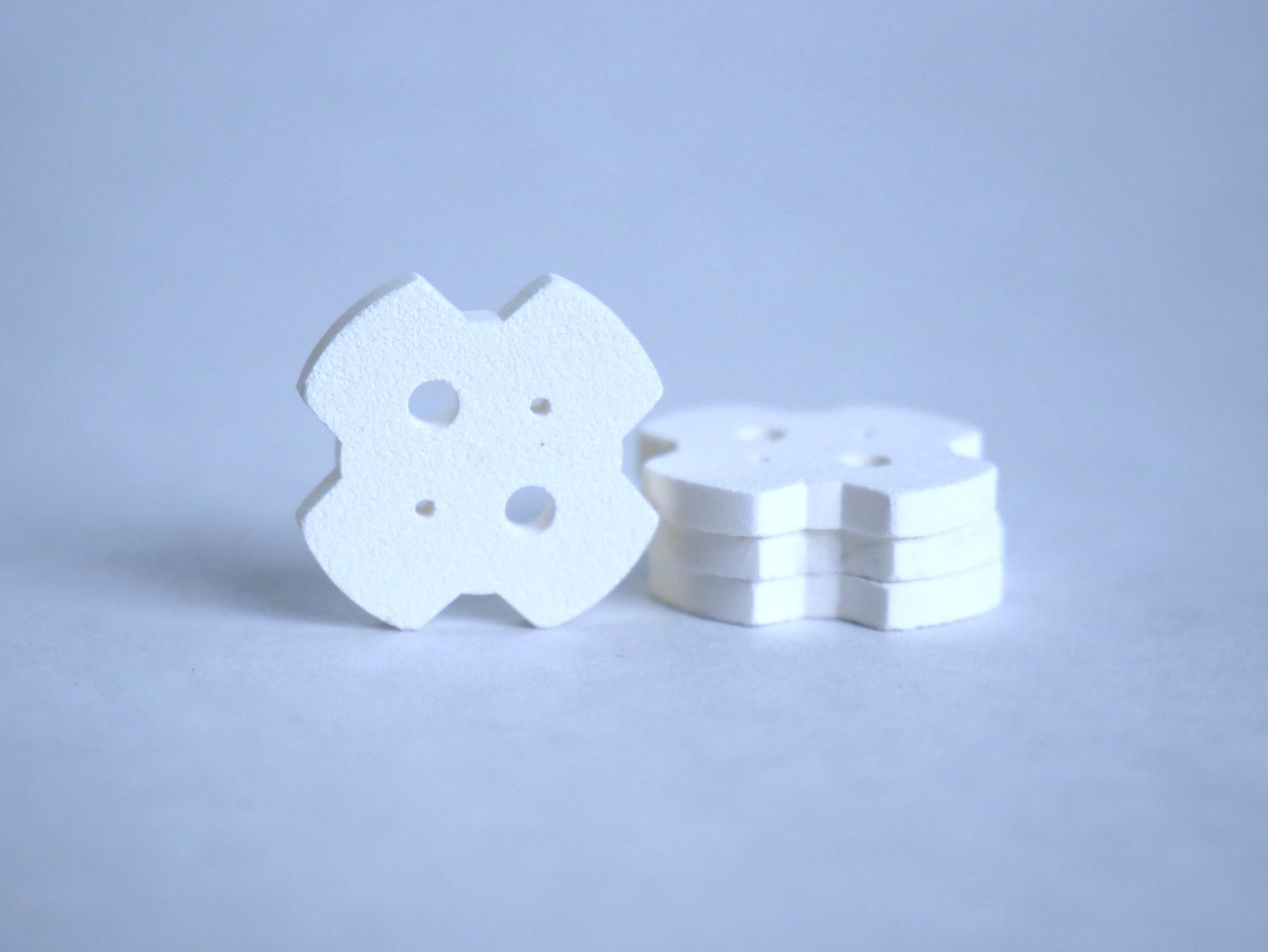

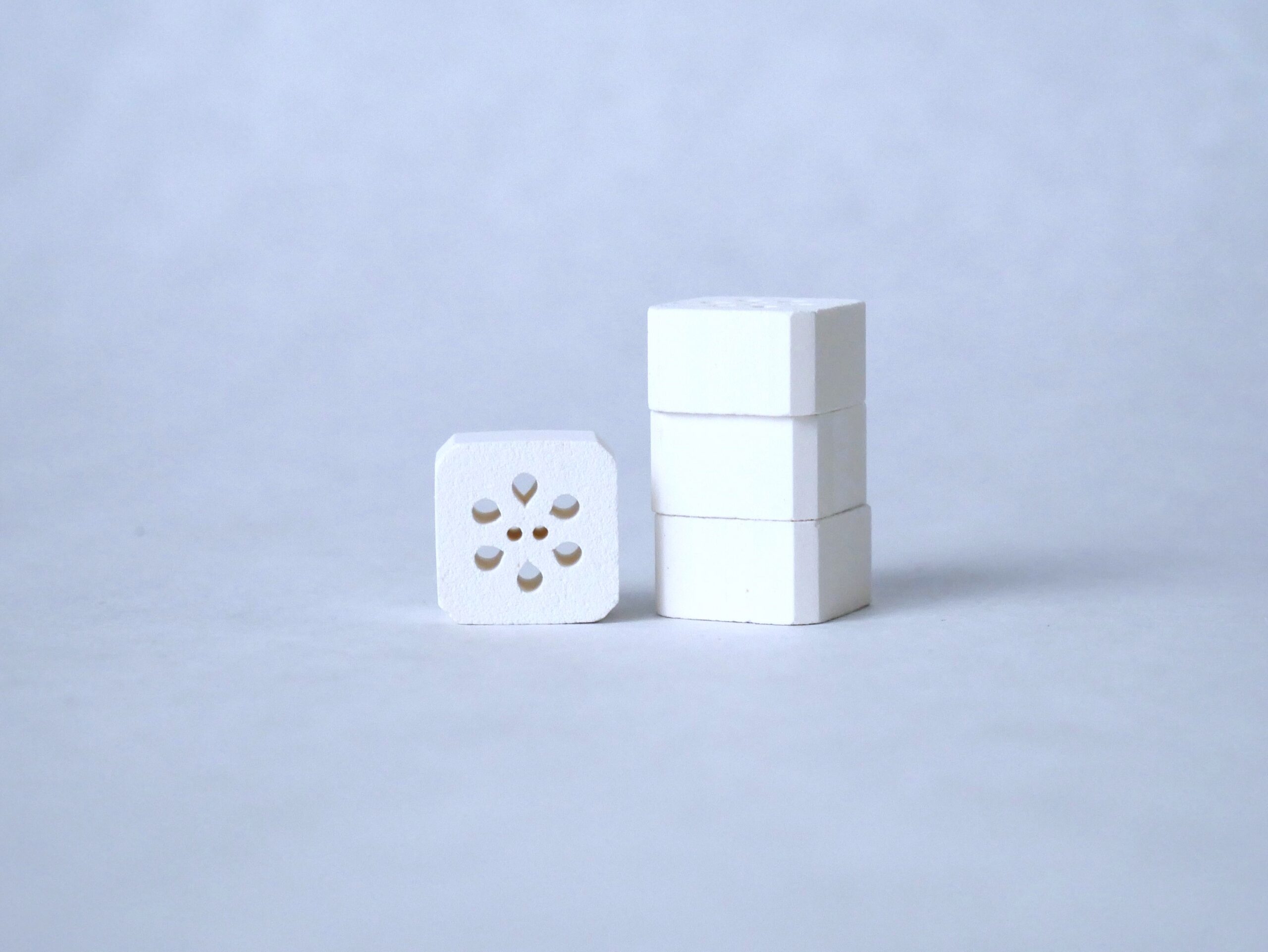

Crushable insulators are rigid tubes, rods, and multi-hole configurations available at lengths up to about 200 mm (<30:1 L/D recommended) and generally round (not required) configurations of constant cross-section (required).

These insulators are designed to be inserted into the metal sheath with conductor elements already threaded in them. The assembly is then swaged or drawn to crush the insulator into a fine, flowable powder which will allow elongation of the cable and tightly compact to maintain separation and electrical insulation of the metallic components.

They may be designed to crush very easily to protect soft platinum components, or with more integrity to improve handling and performance properties. Please refer to the strength specifications

High Purity (99.4+%) & Ultra High purity (99.7+%) MgO

Tateho Ozark can supply all your technical ceramic needs!

Heater grade (98.0+%) MgO

OZARK did not enter the commercial MgO heater market until 1997. The previous 15 years of experience were limited to high purity MgO powders with a minimum 99.4% MgO content. This limited our ability to address the high performance cartridge heater market. The commercial market can not support the raw material costs, and many electrical and mechanical properties are improved with the ability to have beneficial silica, alumina, and lime content.

The vertical integration of the TATEHO OZARK extruded product family into heater and electrical grades has occurred very systematically. This makes TATEHO OZARK unique as the only company with total MgO capabilities in casting, extrusion, and pressing at all Purities and densities. In 2015 – Tateho Chemical Industries acquired OZARK and establishes TATEHO OZARK Technical Ceramics (TOTC)! Our relationship with our sister company (TateCera) in Une, Japan where highest quality MgO powders are produced and manufactured into Ceramics keeps our future MgO supply prospects secure. TATEHO is synonymous with high quality fused MgO for over 50 years. OZARK had a pipeline to them as a favored customer since inception. We now have the ability to create more designer blends because of our new ability to work directly with the excellent Engineers, Scientists, and Technicians at TATEHO.

TATEHO OZARK has learned a lot from our technical interactions with our excellent customers and are able to communicate about important issues regarding the form, fit, and function. Please explore our various product descriptions, with the understanding that not all technical labels and jargon are universal, and our categorizations may be inaccurate or incomplete.

Some main points about TATEHO OZARK heater products

- High Quality MgO grades custom made in our Japanese Global leading facility.

- OD sizes from 0.062″ to 1.0″ (1.5mm – 25mm)

- Round, oval, triangular holes

- Complex hole configurations

- Excellent camber properties

- Customer specified hardness – strong engineering support