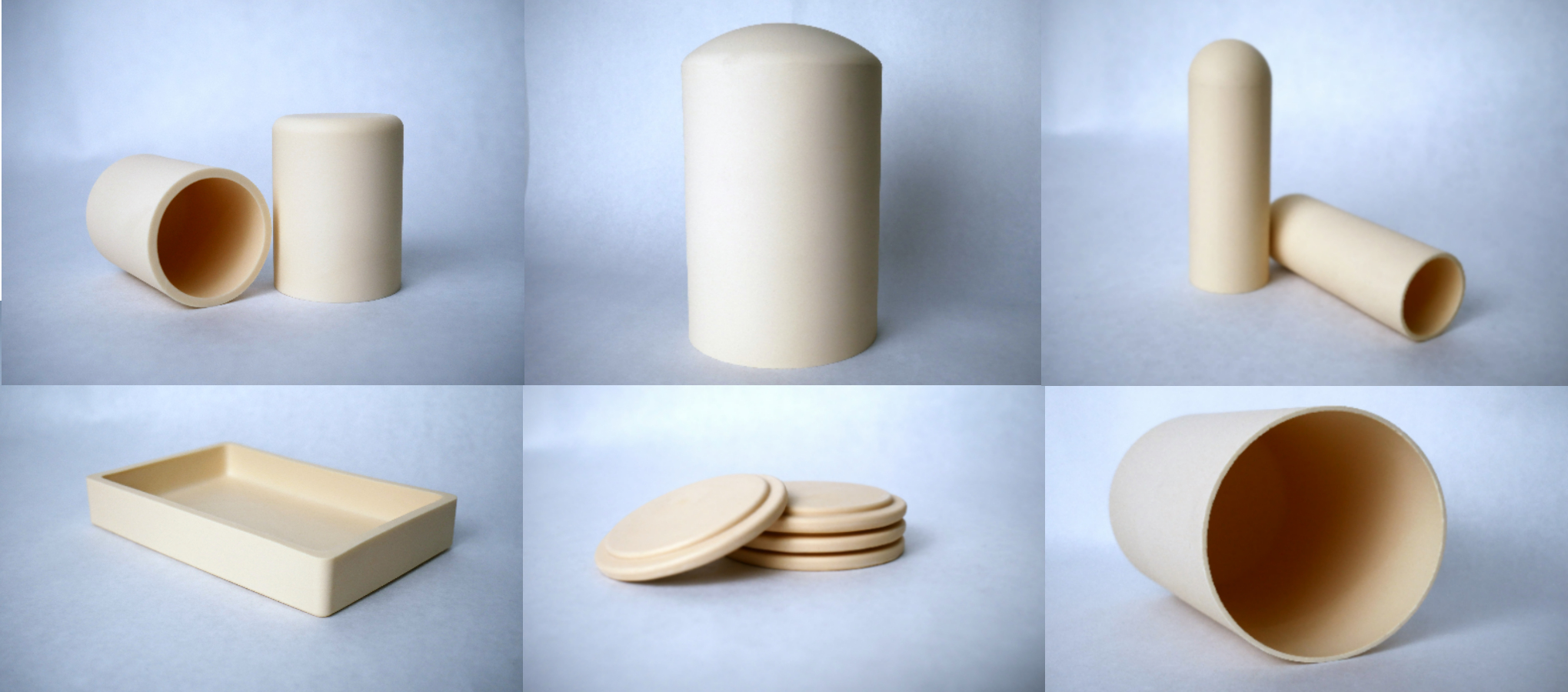

Crucibles from

99.4% MgO and 99.6% Al2O3

Slip Casting is the method of choice for production of Crucibles, tubes, boats, trays and similar hollow or container related shapes. It is of limited use for production of plates, and sheets, and cannot be used for bars, bricks or other shapes with thick cross sections exceeding 3 mm. It is very difficult to slip cast MgO, however, and TATEHO OZARK has improved and commercialized techniques developed by Los Alamos National Labs during the Manhattan project.

TATEHO OZARK’s Slip cast MgO parts have excellent microstructure and achieve +95% of theoretical density routinely. TATEHO OZARK also produces a basic high purity Alumina cast body as a competitive alternative to other sources.

Production Capacity of Slip Cast MgO is adequate to meet demand and can easily be stepped up as OZARK retains a large reserve of MgO raw material. Please refer to our design guide for dimensional limitations, or contact us to push the envelope!

Fine grained, High Density crucibles, trays and shapes.

Many convenient stock sizes from 0.5” to 6” diameter.

Suitable for processing exotic alloys, actinides, and PZTs.

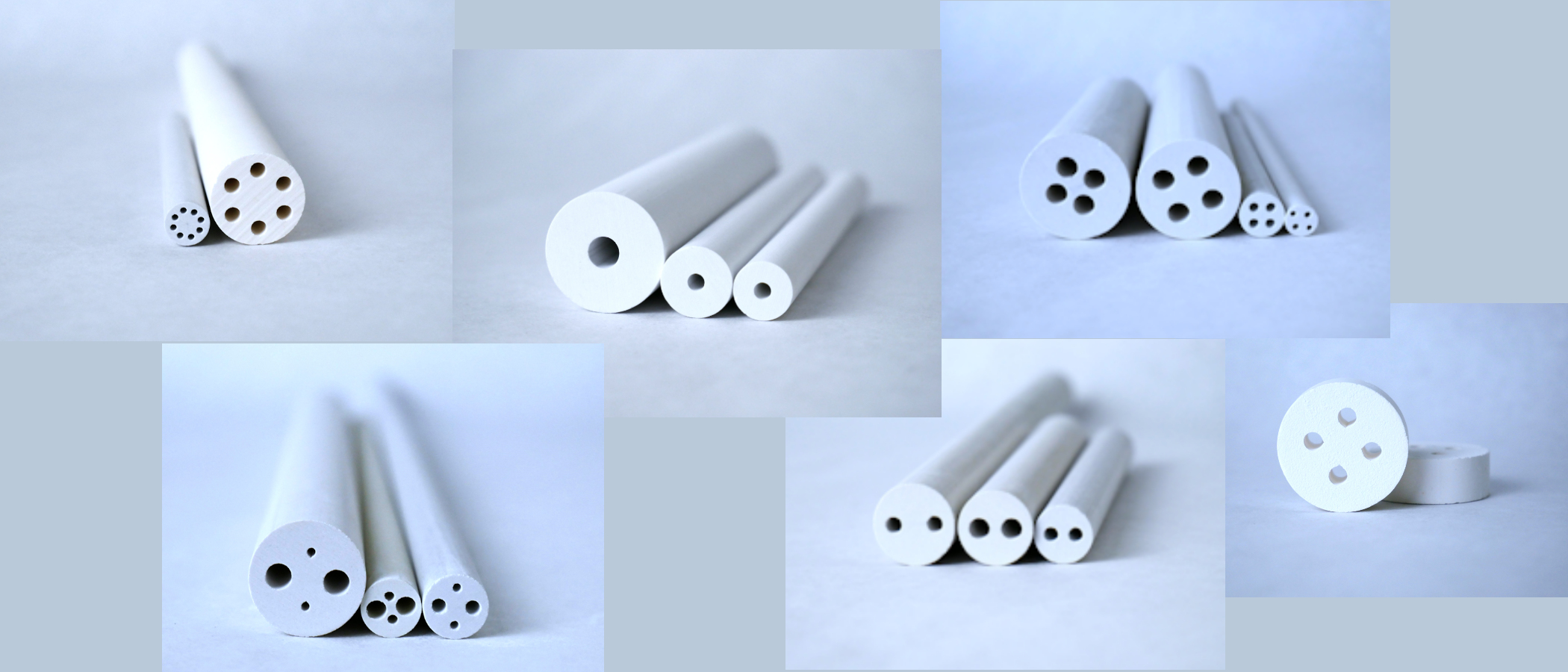

Extrusions for

Thermocouples, MI Cable, and Heaters

Extrusion is the method of choice for production of elongated shapes with a constant cross section. It is easily done with most traditional and advanced ceramics, but is quite difficult with MgO. TATEHO OZARK has developed techniques to produce MgO, HfO2, and Al2O3 extrusions with optimum particle size and microstructure characteristics. The emphasis on powder characteristics is important to guarantee the final product for the user, whether it be for electrical, thermal, refractory, or even high pressure geological applications.

TATEHO OZARK has 5 extrusion presses that are all optimized for tasks ranging from very complex shapes, very small shapes, and production volumes of large shapes. All of this production equipment is supplemented with appropriate Mixing equipment, Drying fixtures, a toolroom, and the most important ingredient, a highly skilled staff of technician/craftspersons/operators. The total production capacity easily exceeds 10 million feet per year, and high volume jobs are routinely handled alongside special small orders.

Our Extruded Products are custom made to specification for dimensions, density, mechanical, and electrical properties. We service a wide range of markets from exotic thermocouple probes in the aerospace and nuclear industry to low cost heaters used in consumer products.

Crushable and hardfired in sizes .030 to 1.00 Inch

Various grades of Magnesia, Alumina and Hafnia.

Stock sizes, no tooling charges, fast track delivery.