INTRO:

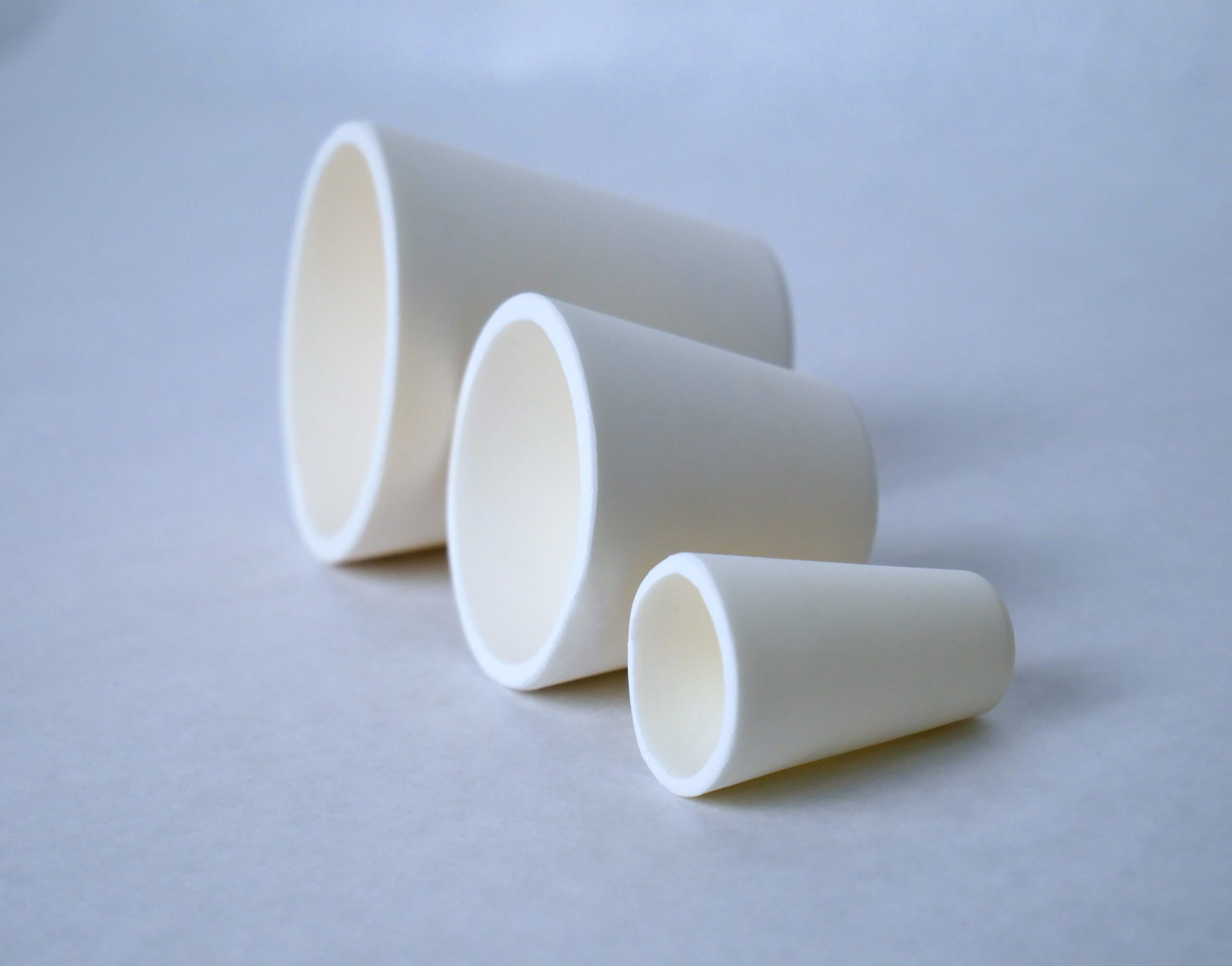

TATEHO OZARK specializes in magnesia ceramics, but many of our customers also use alumina ceramics for various applications. TATEHO OZARK manufactures 99.5% alumina crucibles and trays in the same sizes and price range as our magnesia products.

What are the Specs? A quick synopsis:

Purity: 99.5% minimum Alumina

Density: > 3.7 gm/cc minimum, typically 3.85 gm/cc. (Theoretical density for Al2O3 is 3.98 gm/cc)

Porosity: Typically 4%, less than 1% open porosity.

Dimensions: Most of the same limitations as for MgO, the normal fabrication range is for diameters less than 5 inches and lengths less than 8 inches.

Wall thickness: As with MgO, the nominal wall thickness for most shapes is 0.125” (or 3mm), and the maximum thickness available is about 0.2 inch (4mm) and the minimum is about 0.08 inch (2mm).

Other: Surface finish may vary, but is usually smooth. Surface is not usually “vitrified”.

Design Guides

The design guides are common to both MgO and Al2O3 slip cast bodies which are made by the same production processes.

ABOUT Slip Casting

Every part must begin with an aluminum master pattern (positive) of the same shape, but enlarged dimensionally to compensate for process shrinkage. Plaster molds (negatives) are pulled from the master. Multiple molds are needed for each casting run.

Many patterns and molds are available. Custom shapes will require set-up charges and sufficient lead time for mold master and mold production. The green parts require drying time, trimming to length, and firing to produce the finished product.

SHAPE

High quality alumina shapes are made by slip casting. Slip casting is suitable for production of hollow shapes with uniform wall thickness and an opening to the interior. This is ideal for shapes such as crucibles, trays, boats, etc. There should be no re-entrant angles along the longitudinal cross section of the part (such as Ell-shapes, Crosses, etc.).

Slip casting will produce a variety of shapes as indicated above. Surface finish does not approximate that of machined surfaces. Nominally flat surfaces, such as lids, crucible and tray bottoms, and plates will be concave or convex after firing. If precision dimensions or flat surfaces are required, additional wet diamond machining is required, and many limitations apply.

SIZE

The normal fabrication range is for diameters less than 5 inches and lengths less than 8 inches. Larger parts can be made upon request, at some sacrifice in cost and dimensional control. Please inquire for further information.

The nominal wall thickness for most shapes is 0.125” (or 3mm), and the maximum thickness available is limited to 0.2 inch (4mm). The wall thickness must be uniform throughout the part.

TOLERANCES

Unless tighter tolerances are specified, dimensional tolerances for diameters, heights, and lateral dimensions are 0.125 inch or 5%, whichever is less. These tolerances apply to nominal dimensions only, and do not apply to out of round conditions or distortions. Please consult us if dimensional constraints are important so that the tolerances and inspection methods may be clarified. Other visual inspection criteria will be supplied on request.

DENSITY

Slip cast crucibles exhibit fine grained microstructure and low open porosity. The bulk density of alumina is typically a minimum of 3.7 gm/cc, or 94% of theoretical. Open porosity is less than 1%.

PURITY

All slip cast alumina products are manufactured from high purity calcined aluminum oxide.

Typical Analysis:

| Al2O3 | 99.60% |

| CaO | 0.04% |

| SiO2 | 0.02% |

| MgO | 0.06% |

| Fe2O3 | 0.04% |

| Na2O | 0.08% |

STRENGTH

Fired alumina parts have reasonably good mechanical strength and reasonably good thermal shock resistance. However, the thin walls limit the mechanical strength and charge weight the crucibles can tolerate. Please consult us with any questions concerning physical properties.