What is Hafnia? (HfO2, or Hafnium Oxide)?

Hafnia is the fully oxidized compound of Hafnium (formula HfO2), which is related to Titanium and Zirconium in the periodic table. Hafnium is the first element after the rare earth family, and precedes the Noble metals of Tantalum, Tungsten, Platinum, Gold, and etc.. It is an important material in the Nuclear power industry by virtue of it’s affinity for neutron capture.

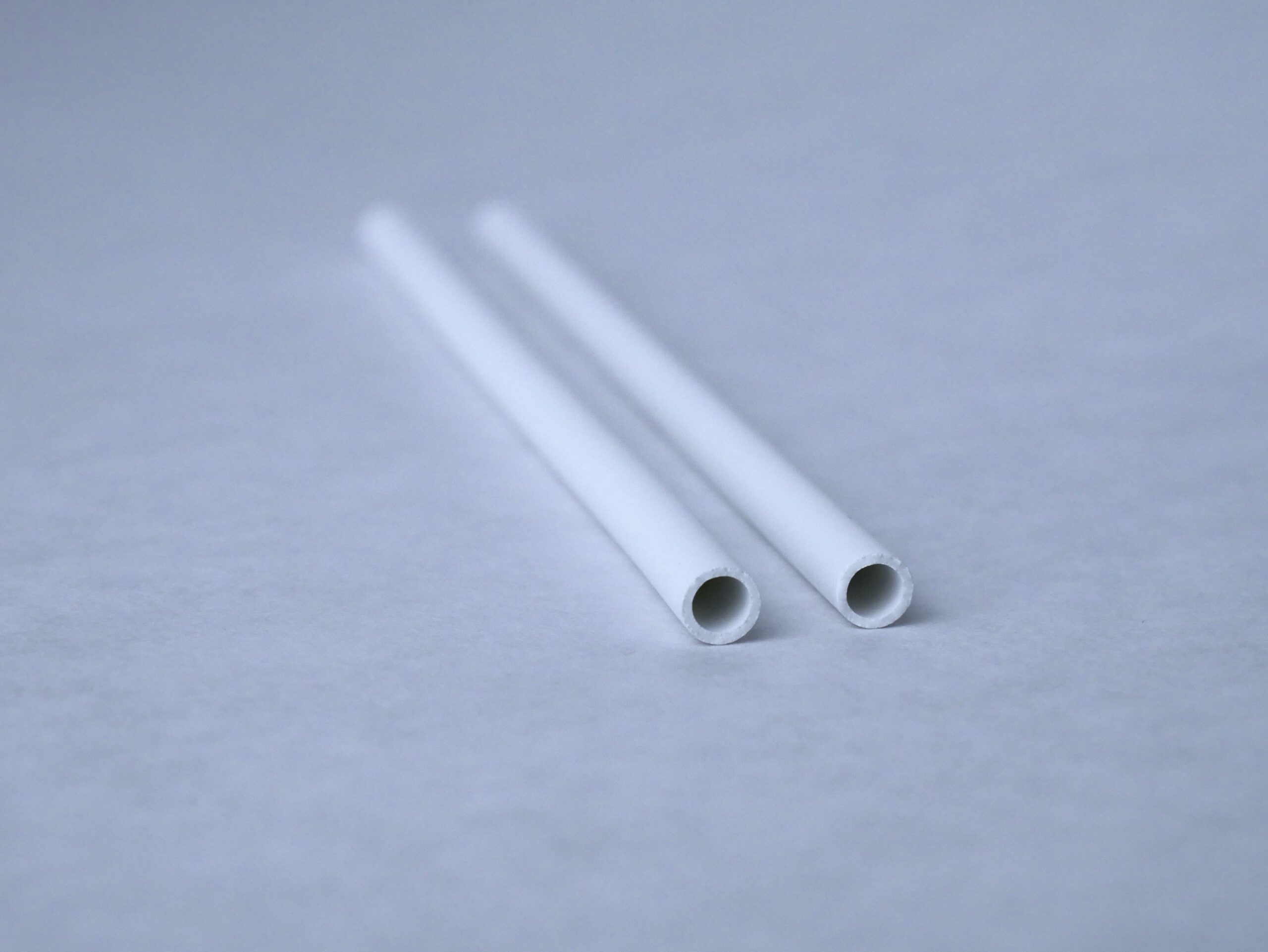

Hafnium Oxide is a very refractory high temperature material which is stable in air and inert environments. TATEHO OZARK adapted our extrusion processes to make high purity Hafnia insulators for use in the high temperature sensor industry.

Hafnium Oxide insulators are used for high temperature type C, R, or S thermocouples and other non-letter designated high temperature types. It is needed because MgO insulation is limited to about 1500 C because of interactions with the metallic elements.

Prior to the commercial availability of Hafnia, Beryllium Oxide was the only option for very high temperature use. BeO is a Group I carcinogen and is prohibited in most facilities because of potential liability issues. It is very difficult to obtain commercially and BeO hardware is not welcome in most facilities.

Advantages of HfO2 – It’s NOT BeO!

No environmental concerns! HfO2 is not a known biohazard at any level, and requires no special handling beyond normal precautions for powders.

- Hafnia has successfully replaced BeO in applications to 2500 C.

- Standard sizes are available from stock, and custom sizes on request.

Normal thermal conductivity for ceramics – BeO is unusually high which is more difficult to manage the transition out of the hot zone.

Standard Sizes

TATEHO OZARK maintains selected standard configurations as stock items and many other special sizes. The following sizes are usually in stock:

| 2015 eff. date | Part No. | O.D. | I.D. | Qty price 0-299" | Qty price 300-1200" | Qty price 1200-3000" | Qty price +3000" |

|---|---|---|---|---|---|---|---|

| 2-Hole Shapes | HUH2039x010 | 0.039 | 0.010 | $6.25 | $5.75 | $5.25 | $4.75 |

| HUH2048x012 | 0.048 | 0.012 | $6.25 | $5.75 | $5.25 | $4.75 | |

| HUH2062x015 | 0.062 | 0.015 | $4.75 | $4.50 | $4.25 | $4.00 | |

| HUH2075x018 | 0.075 | 0.018 | $5.50 | $5.00 | $4.50 | $4.25 | |

| HUH2085x023 | 0.085 | 0.023 | $5.50 | $5.00 | $4.50 | $4.25 | |

| HUH2093x024 | 0.093 | 0.024 | $5.50 | $5.00 | $4.50 | $4.25 | |

| HUH2112x032 | 0.112 | 0.032 | $6.25 | $5.75 | $5.25 | $4.50 | |

| HUH2125x035 | 0.125 | 0.035 | $6.75 | $6.00 | $5.25 | $4.75 | |

| HUH2156x040 | 0.156 | 0.040 | $9.25 | $8.50 | $8.00 | $7.50 | |

| HUH2180x045 | 0.180 | 0.045 | $11.75 | $10.50 | $9.75 | $9.25 | |

| 1-Hole Shapes | HUH1062x031 | 0.062 | 0.031 | $7.25 | $6.25 | $5.75 | $5.25 |

| HUH1125x062 | 0.125 | 0.062 | $7.75 | $7.00 | $6.25 | $5.75 | |

| HUH1125x085 | 0.125 | 0.085 | $7.75 | $7.00 | $6.25 | $5.75 | |

| 4-Hole Shapes | HUH4125x023 | 0.125 | 0.023 | $6.75 | $6.00 | $5.25 | $4.75 |

Custom sizes are available according to the following price schedule (prices per inch). Please allow up to 8 weeks for custom fabrication. Four hole and special configurations must be quoted on a custom basis.

| O.D. size range | min order | min-299” | 300”-1200” | +1200” |

|---|---|---|---|---|

| .030 -.050 O.D. | $1200.00 | $10.25 | $9.25 | $8.25 |

| .051 - .100 O.D. | $1200.00 | $9.25 | $8.25 | $6.75 |

| .101 - .125 O.D. | $1200.00 | $9.25 | $8.25 | $6.75 |

| .126 -.150 O.D. | $1200.00 | $12.25 | $10.75 | $9.75 |

| .151 - .180 O.D. | $1200.00 | $15.25 | $13.75 | $12.25 |

| >0.180" | Inquire | Inquire | Inquire | Inquire |

Insulators are supplied in random lengths, normally between 1 and 4 inches. Longer lengths up to 9 inches may be available. TATEHO OZARK cannot guarantee the squareness or finish of the ends for small sizes or crushable composition. Insulators may also be obtained in soft-fired crushable form, please specify grade CUH.

Purity

All TATEHO OZARK Grades are made with “spectro” grade material from our vendor. The source material is an enriched feedstock from the purification of Zirconium for manufacture into Zircalloy tubes for nuclear reactor applications.

Hafnium and Zirconium both reside in column IVA of the periodic table. The chemical properties are very similar, and they are frequently found together. The Oxides of both metals are very similar as well in their refractory nature and inertness to chemical attack. Zirconium Oxide (ZrO2, or Zirconia) has limited thermocouple insulator applications because of its electrical properties. It becomes conductive at about 1000 C and is actually used as a heating element for high temperature furnaces.

The purification process for Hafnia is capable of rendering a very pure product with respect to all elements except the ubiquitous Zirconia. There is no practical purification method to reduce the Zirconia content below these results. A review of various production lots shows an average Zr content of 0.39%. All other impurities amount to a maximum of 200 ppm (.02%), resulting in typical HfO2 + ZrO2 content of 99.8%. The small amount of ZrO2 does not harm the high temperature metallurgical inertness of the Hafnia, and has negligible effect on the electrical properties.

TATEHO OZARK suggests the following specification for this product.

Hafnium Oxide Chemistry Specification (starting powder basis) – Typically

HfO2 > 98%

HfO2 + ZrO2 > 99.8%

Certification Protocol

TATEHO OZARK uses the vendor’s raw material analysis for the purpose of Chemical Certification. TATEHO OZARK does not offer Chemical Certification based on the fabricated part. This is according to standard industry practice to use the chemical analysis of the raw material as a proxy for the finished part.

TATEHO OZARK’s manufacturing methods are expected to contribute no more than 30 ppm of elemental impurities to our extruded product as a result of contact with processing equipment and kiln furniture. This result has been confirmed with before/after analysis of MgO, Al2O3, and even Y2O3 extruded parts.

In conclusion, TATEHO OZARK certification paperwork is based on the analysis of the initial raw material only.

GRADES

TATEHO OZARK designates Hafnia grades as CUH, HUH, and DUH. All grades are from the same purity feedstock and may be represented as 99+% Hafnia. The first letter distinguishes between our Crushable, Hard fired, and Dense grades respectively. (Note- some legacy batches may also replace the second letter with “R” which simply designated a specific processing step.)

HUH Grade

Typical density of this grade is 8.0-9.2 gm/cc, or about 90% of theoretical density. This is our mainstream Hafnia product which is suitable for use in any sheathed application. Please review technical considerations for potential strength and shrinkage issues.

CUH Grade (and disclaimer!)

Typical density of this grade is 4.5-5.5 gm/cc, or about 50% of theoretical density. The crushable HfO2 product is not a direct analog to our MgO product. Our MgO product is capable of easy loading, then crushing to a fine powder with one swaging or drawing which does not abuse the thermoelement wires during subsequent iterations.

CUH grade is basically an “underfired” ceramic body. As a result, it is subject to further dimensional changes with use, but worse, it can partially sinter into abrasive particles at the low temperatures used for annealing between draws or swages. TATEHO OZARK does not recommend grade CUH for multi-pass cable production with metallurgically required annealing steps.

The CUH grade is suitable for single pass processing, or use without swaging. The user must be aware of the potential for further shrinkage of the insulators and stress to the conductors at high temperature use, as well as the potential development of void regions in the assembly due to shrinkage on the longitudinal axis.

DUH Grade (and disclaimer!)

TATEHO OZARK (sometimes) can offer an overly dense grade, typically 97% of theoretical density. This is not recommended for typical use because the insulator is very brittle as a result of excess grain growth. Availability depends on the status of current powder lots because they are not all suitable for hyper-dense production. There is no increased performance with DUH grade but it may be used to prevent assembly voids in high temperature long duration applications.

MECHANICAL PROPERTIES

STRENGTH

Hard fired Hafnia is not a strong ceramic material akin to Alumina. Comparative strengths are shown below for TATEHO OZARK products. The low density MgO grades (“C” as first letter) are engineered to the strength ranges obtained. The MOR value is from the industry standard flexural bend test.

Grades Description Applications MOR

DUH High Density Hafnia High Temp thermocouple <800 psi

CUH Crushable Hafnia High Temp thermocouple 2-6 Ksi

CSM, CUM Crushable MgO (typical MI cable apps) 3-8 Ksi

CTM Swageable MgO (typical heater apps) 4-10 Ksi

CTMh Non-Swageable MgO (cable heater apps) 8-14 Ksi

HRM Hard Fired Dense MgO Electrorefining 15-25 Ksi

HUH Hard Fired Hafnia High Temp thermocouple 5-30 Ksi

HLA Hard Fired Al2O3 Unsheathed Thermocouple 80-150 Ksi

TATEHO OZARK uses a reactive Hafnia powder which fires to about 90% dense at a relatively low temperature. There is a possibility of 1-2% additional shrinkage in all dimensions after excursions to 1800 C or above. TATEHO OZARK does not know if the low strength of the product is a result of intrinsic material limitations, or the limits of fabrication technology.

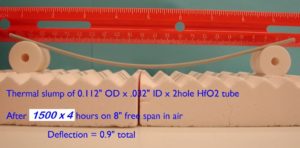

CREEP STRENGTH

TATEHO OZARK HfO2 insulators should not be used in a free-standing application without careful consideration of support requirements. It is recommended to use in a metal sheath suitable for the environment. The creep strength is insufficient to support itself, even at modest temperatures, as demonstrated in the photo:

PHASE TRANSFORMATION

The purpose of this discussion is to inform the user of a potential for unexpected performance results at temperatures above 1650 C. It is helpful to explain the situation with a discussion of Zirconia:

Zirconia is well known for its phase transformation upon heating. This has led to an entire family of materials known as partially and fully stabilized Zirconias. This phase transformation is associated with a volume change (expansion on cooling), which causes cracking and degradation with thermal cycles. However, the addition of 1-8% of “stabilizing” cubic molecules (MgO, CaO, Y2O3) strengthen the tetragonal or cubic phase and are used to produce toughened ceramics, which have widespread engineering applications.

As a Group IVA neighbor in the periodic table, it is no surprise that Hafnia also makes a phase transformation, but at a higher temperature (not until 1650 C). Hafnia is monoclinic at temperatures up to 1650 C, at which point a transformation occurs to the tetragonal phase. This transformation reverses back to monoclinic phase upon cooling back to room temperature.

The volume changes attendant to this phase transformation are not as extreme as ZrO2, and empirically no deleterious effects have been reported to TATEHO OZARK by our customers. We have knowledge of units that have been cycled to 2500 C for over 100 cycles, at which point the failure was tungsten related, not the ceramic.

It is possible to “stabilize” HfO2 with small molecules similar to ZrO2, but pre-made powders are not readily available. TATEHO OZARK has produced blended ingredients on special request for customers, but we do not presently offer any stabilized Hafnia compositions. It is not established whether a stabilizing effect occurs with simple powder blending.

HYGROSCOPICITY

HfO2 extrusions from TOTC are free of moisture and volatile impurities, as confirmed by experiment up to 5 years of shelf life.

If desired, customers may bake them at 100C or 400C with no consequences or effects.

DIMENSIONAL PROPERTIES

STRAIGHTNESS vs. LENGTH

All extrusions are fired horizontally. Because of the high density of the green body and the high shrinkage in firing, it is not possible to produce unlimited lengths. The high shrinkage rate requires the ends of the part to move many times the part diameter, and setter friction produces tensile forces that tear the part in half and leave residual stresses. An upper limit seems to be the lesser of 100 diameters or about 9” finished length. Please consult TATEHO OZARK if long lengths are required. When no length is specified, TATEHO OZARK typically makes uniform lengths from 2 to 4 inches.

The Straightness of fired Hafnia insulators is influenced by diameter, length, and processing variables. TATEHO OZARK manages these variables as much as possible, but due to the high shrinkage attendant with firing, there is some variation that cannot be controlled. There are no practical grinding or post-firing options to improve straightness. The default spec for straightness is 0.005 in/in, and in actual practice the median straightness is about .0025 in/in. If you have a maximum envelope for straightness and diameter, or a Ring Gage size, please advise and we will attempt to meet your criteria.

END FINISH and Length Tolerances

Hard Fired hafnia products are fired at maximum lengths, and broken by hand to approximate finish length. In some cases, the broken end will be ground flat, but not at the risk of clogging the hole or contaminating the ceramic. Many parts are supplied with as-broken ends. Length tolerance for fixed lengths is typically +1/4”/-0. If end squareness, uniformity of length, and/or straightness are mission critical, please consult TATEHO OZARK to discuss alternatives and unintended consequences.

DENSITY and Latent Shrinkage

The as-fired density of HUH grade hafnia varies from lot to lot and somewhat as a function of part size. If you have mission critical requirements, please advise TATEHO OZARK. TATEHO OZARK does not use absolute density as a control specification. .

The median density result is about 9.0 gm/cc, but in some cases, may be as low as 8.0 gm/cc. It is possible or even likely that the insulator pellets will shrink in your application at temperatures above 1500 C. The expectation for normal grade HUH parts is a worst case scenarios of latent shrinkage from 2 to 4% of linear dimensions. That is, a 0.125” outside diameter could shrink to 0.120”, or a 0.035” hole might shrink to 0.034”. This is unlikely to damage conductors or sheath materials, but may result in gaps between insulators. Please consider the possible consequences of additional shrinkage in your application.

Reactivity

For over three decades, our HfO2 insulators have been used in furnaces with oxidizing (air), inert, vacuum, and reducing atmospheres with no reported problems. We have no information about halogen or forming gas applications.

There has been no reported interaction with direct contact with solid materials such as refractory metals (thermoelements and sheath materials like W, Pt, Re, Mo, or with graphite furnace components.

We have no information about possible risk of contact with glass-forming materials such as B2O3, LiO, or SiO2, etc… These materials are usually not involved in the high temperature arena where HfO2 is used.

We are happy to provide suitable sample pieces for your compatibility testing.

COLOR

Hafnium Oxide powder is white in color. CUH grade insulators at ~50% density are also white in color but DUH grade insulators at 98% density are dark gray. HUH grade insulators vary from light gray to dark gray and typically exhibit a parchment or mottled pattern. Color variation within the gray palettes is not considered a cause for concern for any of these grades.

The reflectivity of the surface seems to be related to the microscopic porosity distribution which is a function of density. Some support for this model comes from the subtle variations which correlate to flow artifacts of the mud. The surface of an extruded insulator is typically denser than the interior, and flow lines relate to the viscosity of the mud and the creation of local density gradients. There also might be related surface texture effects whereby the intensity varies like the nap of a rug.

TATEHO OZARK has been informed of insulators becoming snow white at very high temperature. TATEHO OZARK has not confirmed this observation, and does not know the environmental conditions. We do not know if these reports of color changes apply to oxidizing, vacuum, or reducing atmospheres. We do not expect any color changes as Hafnium is steadfast as a tetravalent atom and is a “getter” for oxygen.