INTRODUCING – Crushable Spinel cores

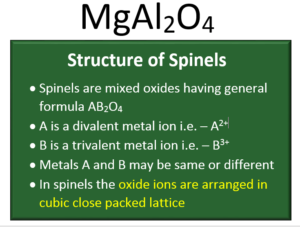

Spinel is the mineral name associated with an equimolar composition of MgO and Al2O3, resulting in a formula of MgAl2O4. The name is associated with many derivative and substitution compounds and defines a major classification family in crystallography. It also is a semi-precious gemstone when found with sufficient crystal quality and the right coloration caused by impurities.

Spinel has been a material of interest as an alternative to MgO for MIMS cable because of the potential to resist ambient humidity. The electrical properties of MgO are severely affected by brief exposure to ambient humidity conditions. This effect of humidity on exposed MgO insulation is an inconvenience at best, and requires special precautions to seal exposed ends for even short term storage.

The mechanism for such a profound effect is not known. It may be due to:

- A lowering of the activation energy for the formation of Mg++ ions, which are the principal charge carriers in MgO

- The possible substitution or addition of H+ ions as the charge carrier

- Alternately, the effect could be due to the hydration reaction of MgO with moisture to form Brucite (MgOH2). Since Spinel does not readily hydrate, it may have potential to avoid this problem.

TATEHO OZARK has selected a commercial grade of Spinel for development. To date, some tests have been encouraging, but no magic bullet has been revealed. TATEHO OZARK is making Spinel parts available as an alternative, with no expectations of performance.

USES:

1) possible improved moisture resistance when exposed?

2) possible impedance performance for AC frequencies?

3) possible performance improvements for high temperature insulation resistance?

4) possible cost advantage compared to type 1 MgO materials?

PURITY:

TATEHO OZARK acquires Spinel powder from a commercial source that manufactures bulk quantities for the refractory industry. Thus, our supply is stable, plentiful, and potentially will offer cost advantages in production quantities.

The Spinel powder for this application is actually considered “alumina-rich”. A perfect equimolar ratio results in a 71.6% Al2O3 content, and our SPN grade is designed for a slight excess Al2O3. The principle is to reduce the amount of free MgO in the solid solution, so that the powder does not mimic the undesirable moisture sensitivity of MgO.

Grade SPN Spinel crushable insulators - Typical Analysis

Al2O3 73.84%

MgO 25.04%

CaO 0.29%

Na2O 0.26%

Fe2O3 0.01%

SiO2 0.54%

K2O 0.02%